summary:

Viny1 acetate (VAC) is an important organic chemical raw material, which is widely used in the manufacture of polyvinyl acetate, polyvinyl alcohol and further processing for adhesives, coatings, vinylon fibers, fabric processing, lotion, resins and films. The production routes of vinyl acetate include acetylene method and ethylene method, and the ethylene method has become the main way of producing vinyl acetate in the world. For a long time, VAC technology and its core catalysts have been monopolized by foreign companies, but foreign catalysts have disadvantages such as high prices, sensitivity to changes in reaction materials, poor resistance to material interference, and short catalyst operating life. In order to break through the monopoly of foreign companies on vinyl acetate catalysts and products, improve the performance of catalysts, accelerate the industrial implementation and transformation of patented technologies, we are committed to and have successfully developed new ethylene based vinyl acetate catalysts and related vinyl acetate production processes.

This catalyst has won awards such as the first prize of Shanghai Science and Technology Progress Award and the second prize of Sinopec Science and Technology Progress Award; Based on the core technology of catalysts, combined with catalyst amplification and reaction process research, we have obtained a series of more than 60 Chinese authorized invention patents, including catalyst carrier development, catalyst innovation, reaction process and other technologies.

CTV series vinyl acetate catalyst:

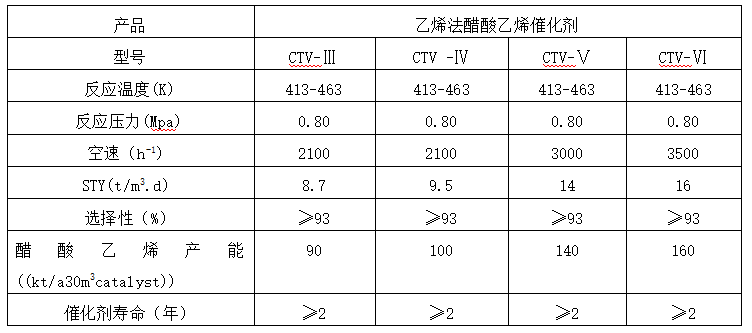

Four grades of CTV series vinyl acetate catalysts have been developed, which can be applied to different industrial plants under different process conditions.

Performance:

The main promoted brand of vinyl acetate catalyst for ethylene process is CTV-IV catalyst, which has the characteristics of high dispersion of palladium alloy and reasonable and uniform particle size distribution of palladium alloy. The industrial application results show that CTV-IV catalyst has the advantages of high average space-time yield, high average selectivity, and long service life when operated on vinyl acetate industrial plants. The comprehensive performance has reached the international advanced level, especially the catalyst life and selectivity are at the international leading level.

Promotion application:

The CTV series vinyl acetate catalyst has been successfully applied in three sets of ethylene based vinyl acetate plants in China.