summary:

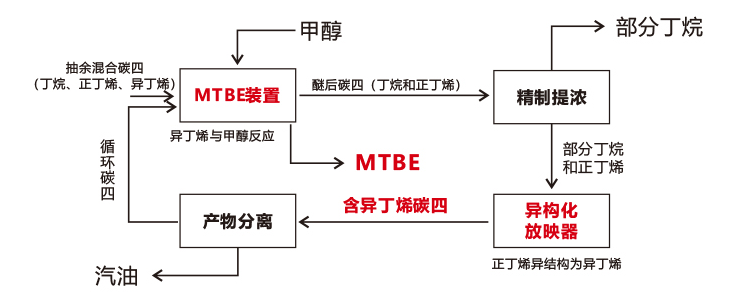

The SBSI-22 catalyst is made from butene as the raw material and produces iso (n) butene through skeletal isomerization. Isobutene is the raw material for producing methyl tert butyl ether, which is mainly used as a clean gasoline additive to increase the octane value of gasoline. Since 2004, comprehensive research has been conducted on the isomerization technology of butene skeleton, and a series of fully crystalline FER zeolite catalysts have been successfully developed.

This project has applied for more than 10 Chinese invention patents in total.

Butene skeletal isomerization technology:

The isomerization process of butene skeleton uses C4 raw materials rich in butene to produce iso (n) butene, and its technical characteristics are as follows:

(1) Extremely low energy consumption: The airspeed can reach 2.0h-1 or above, significantly reducing energy consumption and equipment investment.

(2) Excellent product quality: The highly selective catalyst suppresses side reactions, resulting in a high content of isobutene in the product.

(3) Maximum flexibility of raw materials: Catalysts have good anti impurity performance, and butene raw materials can be used including polymer grade, chemical grade, and refinery grade butene raw materials.

(4) No need for hydrogen: The process does not require hydrogen, the process is simple, and the economy is good.

Butene skeleton isomerization series catalyst:

The main promoted grades of butene skeleton isomerization catalysts are SBSI-22 series catalysts, and the main features of the products are as follows:

(1) High activity: Using a SBSI-22 series of catalysts, the conversion rate of butene is high, and the heating interval of the device is long.

(2) High selectivity: Using a SBSI-22 series of catalysts, the by-product of heavy isomeric oil is reduced, the selectivity of isomeric butene is high, the utilization rate of raw material butene is high, and the overall economic benefits of the device are significant

(3) High stability: Using a SBSI-22 series of catalysts, the one-way lifespan reaches 3 months, the regeneration performance is stable, and the expected lifespan of the catalyst is 2 years.

(4) Environmentally friendly: Catalysts are free of toxic and corrosive components, do not pollute the environment, and can be used renewable.

(5) High mechanical strength: The catalyst has high compressive strength, fully meeting the requirements of industrial applications.

Promotion application:

The isomerization catalyst has been industrially applied in the 320000 ton/year n-butene isomerization unit in Guangdong and the 130000 ton/year isobutene isomerization unit in Ningxia.