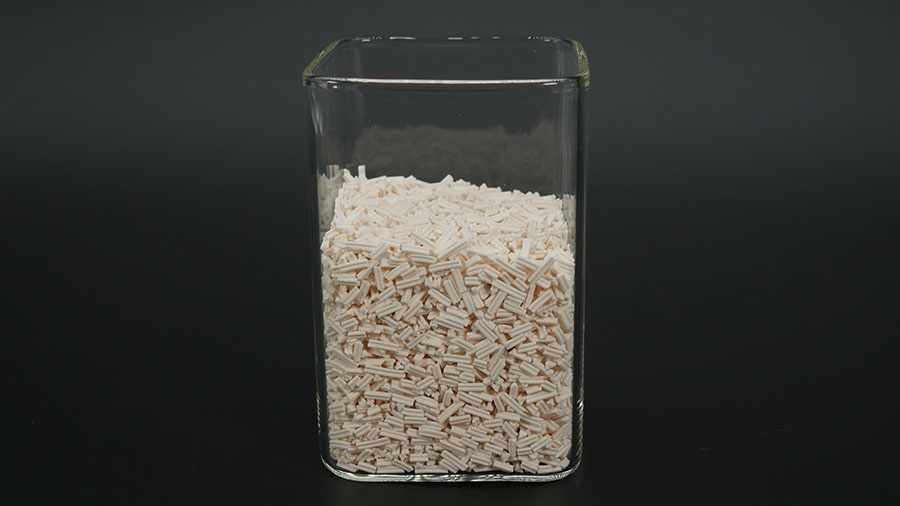

1. Overview

Aviation kerosene hydrogenation catalyst is used in the hydrogenation refining process of aviation kerosene, mainly to remove impurities such as thiol sulfur, nitride, and oxide in the fuel, improve the cleanliness and combustion performance of aviation kerosene, and meet aviation fuel standards. This catalyst is widely used in aviation fuel production and refinery hydrogenation units, ensuring that aviation coal has excellent stability, low corrosiveness, and high combustion efficiency.

2. Product Features

(1) High desulfurization and denitrification efficiency: It can effectively remove thiol sulfur, nitrides, and oxides from aviation kerosene, improve stability, reduce corrosiveness, and pollutant emissions.

(2) Strong catalytic activity: efficient selective hydrogenation, ensuring the quality of aviation coal products meets international standards.

(3) Strong anti toxicity: high tolerance to impurities (such as sulfur, metals, etc.), long catalyst life, and reduced replacement frequency.

(4) Wide applicability: It can be used for various aviation kerosene raw materials, including straight run kerosene, light cycle oil (LCO), etc.

3. Application Fields

(1) Aviation fuel production: Producing aviation fuel that meets international standards such as Jet A, Jet A-1, JP-5, JP-8, etc.

(2) Petroleum refining: Used for aviation kerosene hydrogenation units in refineries to optimize fuel quality.

(3) Military aviation fuel: Improve the stability and corrosiveness of military aviation fuel.