1、Overview

Paraxylene (PX) is an important basic organic raw material, mainly derived from aromatic hydrocarbon complex units using reformate as raw material. The residual trace olefins in the reformed oil will seriously affect the subsequent PX production process and product quality. This technology uses a specific structure of molecular sieve as the catalytic active center under non hydrogenation conditions to convert difficult to separate trace olefins into easily separable high boiling point compounds, which are then removed from the carbon eight aromatic hydrocarbon components. After continuous research on this technology, DOT-100, DOT-200, DOT-300, TCDTO-21 catalysts suitable for the reforming unit of aromatic hydrocarbon complex and IDO-01 catalyst suitable for the isomerization unit have been developed, which have solved the environmental problems caused by the large amount of clay hazardous waste emissions in PX production units and promoted the development of PX green production technology.

This technology has obtained a total of 12 authorized invention patents at home and abroad, as well as 1 second prize for provincial and ministerial level technological inventions. The complete set of aromatic hydrocarbon technology integrated with this catalyst by Sinopec has won the National Science and Technology Progress Special Award.

2、Reforming oil de olefin technology

The non hydrogenation reforming oil catalytic olefin removal technology adopts a liquid-solid fixed bed reactor to remove trace olefins through reaction on molecular sieve catalyst, which is an effective technical solution for improving the quality and efficiency of aromatic hydrocarbon plants. Its technical features are as follows:

(1) Strong applicability: It can directly replace clay and has a simple process.

(2) High olefin removal rate: deep removal of trace olefins, long cycle life, effectively protecting downstream adsorbents and catalysts.

(3) Low comprehensive cost: Compared with traditional clay process and hydrogenation olefin removal process, the cost of olefin removal per ton of aromatic feedstock is reduced by more than 50%.

(4) Environmentally friendly: Compared to traditional clay processing, it has the advantages of stable operation, fewer side reactions, no hydrogen exposure, and renewability. The catalyst used is also friendly.

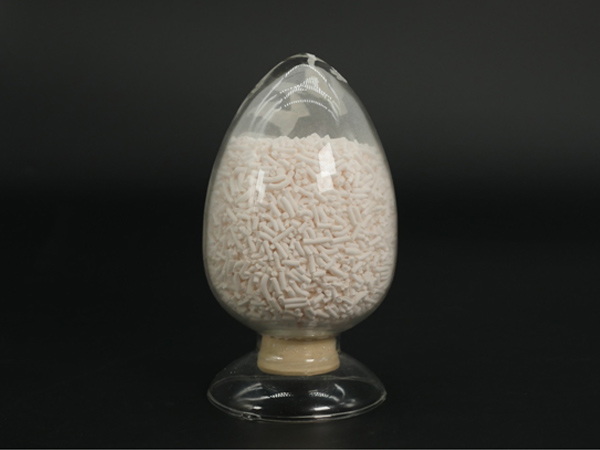

3、Olefin removal catalyst

Reforming oil de olefin catalyst, currently, de olefin catalysts have the characteristics of high activity, good stability, long service life, and renewability.

4、Promote application

More than 30 sets of facilities including Maoming Petrochemical, Zhenhai Refining and Chemical, Yunnan Petrochemical, Sichuan Petrochemical, and Sinochem Quanzhou.