1、overview

Naphtha mercuric removal agent is developed and produced by Jiangxi 863 Industrial Co., LTD. It is a mercuric removal product made of metal sulfide as the main component, adding special additives and molecular framework materials.

Transition metal sulfides are active components that remove mercury and react with volatile mercury to form non-volatile mercury sulfide. The product exists in a very stable form, insoluble in hydrocarbons, insoluble in water, and not volatile in air. In the composition of the demercury agent, the active component is highly stable, insoluble in water and insoluble in oil.

The product has the advantages of high strength, high mercury-removal precision and large capacity. It has a very high reaction adsorption effect on mercury, and is suitable for the mercury-containing hydrocarbon gas and liquid phase material such as natural gas, liquefied gas, petroleum cracking gas, condensate oil, naphtha and so on.

PX-12 mercuric remover is safe, reliable, long life and low cost. All the performance indexes of the product meet or better than the same type of foreign mercuric remover.

2、product physical properties

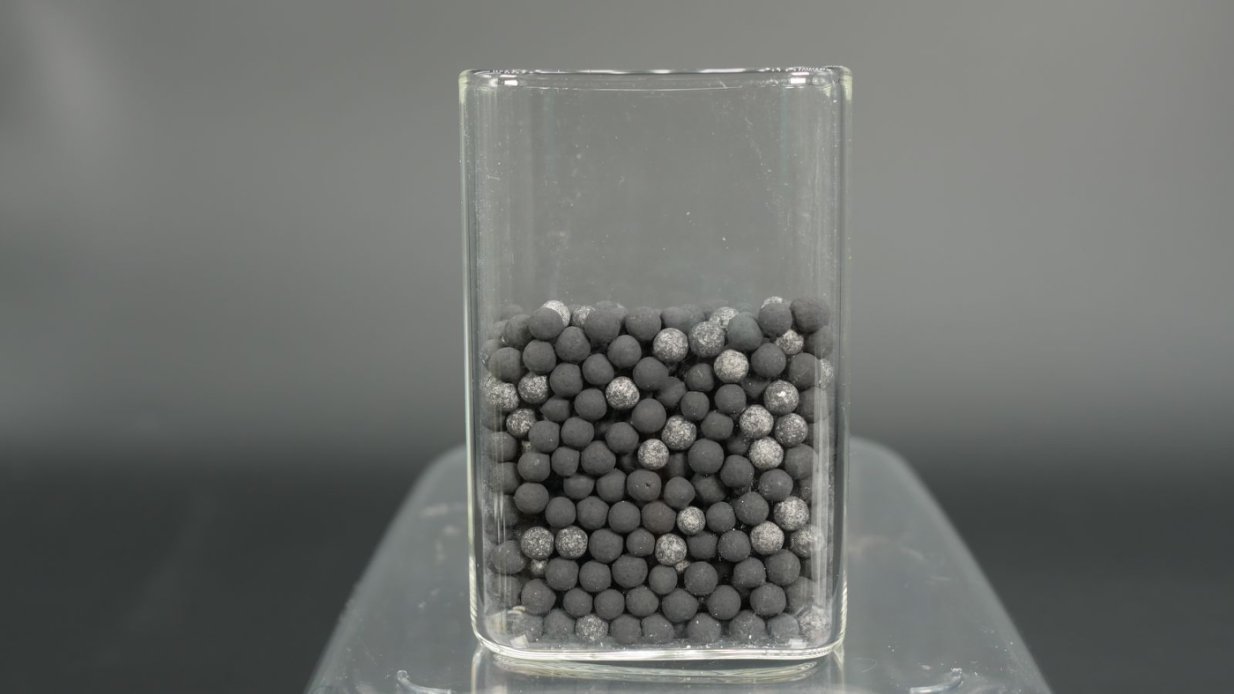

Appearance black ball

Specifications, mm Φ3 ~ 5

Packing density, kg/l 0.6 ~ 0.8

Average crushing force at particle point, N/ particle

40 or higher

Form alumina +CuS

3、Conditions of use and technical indicators

Operating condition index

Temperature /℃ 20-120

Pressure /MPa (g) 1.0-3.0

Liquid phase airspeed /h-1 3-4

Height to diameter ratio 2-5

Inlet HCl content /ppbw ≦10

Export HCl content /ppbw ≦1

4、precautions

1, the product uses Tietong packaging. During transportation and storage, the package should be kept intact to avoid rain. The storage place of mercury agent should be cool and dry and should not be in contact with other chemicals to avoid corrosion.

2, in the filling process, the operator should not directly trample on the dechlorination agent. The charge should be even and flat.